SpaceX is undertaking a transformative $280 million expansion of its Bastrop, Texas facility, positioning the site as North America’s premier Starlink hardware and semiconductor manufacturing complex.

The project represents one of the largest manufacturing investments in Central Texas and reflects SpaceX’s commitment to scaling production capacity for its rapidly growing satellite internet service.

Facility to Triple in Size

The existing 700,000-square-foot Bastrop campus will expand by more than one million square feet over three years, reaching approximately 1.7 million square feet total.

This dramatic enlargement will transform the site from a final assembly operation into a vertically integrated electronics manufacturing ecosystem capable of producing complete Starlink terminals from raw components through finished products.

State Grant Accelerates Project

Governor Greg Abbott announced a $17.3 million grant from the Texas Semiconductor Innovation Fund to support the expansion, making it the second-largest award in the fund’s history.

The state investment reflects Texas’ strategic priority to develop domestic semiconductor and advanced packaging capabilities while reducing reliance on overseas manufacturing.

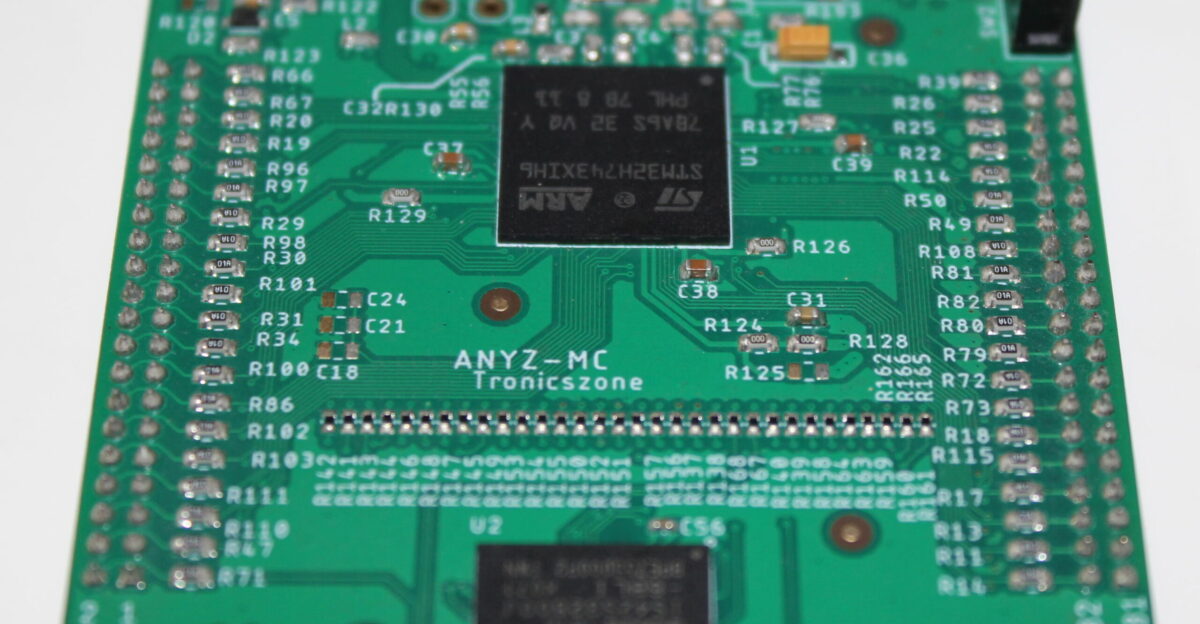

Semiconductor Lab and Advanced Packaging

SpaceX plans to construct a semiconductor failure analysis laboratory and implement panel-level packaging (PLP) technology at Bastrop, moving deeper into the electronics supply chain.

These capabilities will enable the company to control quality, accelerate design iteration, and potentially manufacture custom silicon components critical to Starlink terminals.

PCB Manufacturing Excellence

The expanded facility will house the largest printed circuit board manufacturing operation in the United States, according to SpaceX leadership.

The company claims its highly automated production process will match or exceed Asian manufacturers’ efficiency while reducing supply chain vulnerabilities inherent in overseas sourcing.

400+ Jobs for Bastrop County

The expansion is expected to create more than 400 new manufacturing, engineering, and research positions in Bastrop County.

These roles offer competitive compensation and benefits typical of SpaceX operations, providing significant employment opportunity in a historically rural region east of Austin.

Infrastructure and Amenities

Beyond manufacturing space, SpaceX is investing $8 million in office expansion (80,000 square feet) and undertaking major parking improvements to accommodate workforce growth. The company is also upgrading wastewater treatment infrastructure and investing in local amenities that support employee retention and attraction.

Starlink’s Explosive Growth Drives Demand

Starlink has grown from approximately 2 million subscribers in 2023 to over 5 million by late 2024, driving unprecedented demand for hardware production.

The Bastrop facility currently produces 15,000 terminal kits daily—equivalent to 5.5 million units annually—but the expansion will significantly increase capacity to meet continued subscriber growth.

Production Capacity Expansion

Current production at Bastrop reaches 4.6 million dishes annually, with the expanded facility targeting capacity exceeding 5.5 million units per year by 2027.

This production scaling positions SpaceX to support Starlink’s expansion into direct-to-cellular service, enterprise markets, aviation, and maritime applications.

Vertical Integration Strategy

By integrating PCB fabrication, advanced packaging, and assembly under one roof, SpaceX reduces supply chain dependencies and accelerates design-to-production cycles critical to its iterative engineering culture.

This vertical integration model contrasts with competitors who rely on distributed supply chains spanning multiple continents.

Reshoring Advanced Manufacturing

The Bastrop expansion represents a milestone in efforts to reshore critical technology manufacturing from Asia to the United States.

SpaceX’s decision to manufacture PCBs and pursue panel-level packaging domestically reverses decades-long trends that concentrated these operations in Taiwan, China, South Korea, and Southeast Asia.

Supply Chain Resilience

COVID-19 disruptions and geopolitical tensions exposed vulnerabilities in globalized electronics supply chains, motivating SpaceX’s domestic manufacturing push.

By producing components within the U.S., SpaceX insulates Starlink from shipping delays, tariffs, and geopolitical supply disruptions affecting overseas competitors.

Strategic Government Alignment

U.S. government support for domestic semiconductor manufacturing—including the federal CHIPS and Science Act and Texas CHIPS Act—creates compelling financial incentives for reshoring.

As SpaceX’s largest customer via NASA and Department of Defense contracts, the government has strategic interest in securing domestic supply chains for critical technologies.

Company Town Development

SpaceX’s Bastrop operations are part of a larger “Snailbrook” corporate compound encompassing SpaceX, X (formerly Twitter), and The Boring Company facilities within a 10+ square-mile area.

The companies have acquired approximately 450 acres for employee housing, recreational facilities, schools, and retail amenities, creating a self-contained ecosystem.

Economic Impact on Bastrop County

SpaceX’s operations have contributed nearly $70 million in local economic impact through construction, infrastructure upgrades, and employment since 2023.

Beyond direct employment, indirect effects include real estate appreciation, business growth, and increased demand for services supporting a rapidly expanding workforce.

Infrastructure and Growth Challenges

Rapid employment growth strains local infrastructure including roads, schools, water systems, and emergency services designed for smaller populations.

While SpaceX funds specific upgrades, broader needs require public investment that may lag demand, creating capacity pressures for Bastrop County.

Environmental and Community Concerns

SpaceX and affiliated entities have faced environmental compliance challenges, including wastewater violations and disputes over Colorado River discharge plans.

Community members have raised concerns about rapid cultural change, environmental stewardship, and the concentration of economic power within Musk-controlled enterprises.

National Security Implications

The Bastrop expansion aligns with U.S. efforts to strengthen domestic control over critical technology supply chains essential to national security and economic competitiveness.

Officials frame the project as reducing vulnerability to foreign supply disruptions and geopolitical leverage in strategic industries.

Long-term Vision and Outlook

If successful, the Bastrop expansion could establish a template for reshoring advanced electronics manufacturing across U.S. industries.

SpaceX’s integrated model combining automation, domestic sourcing, and iterative design offers a proof point that competitive unit economics are achievable within the U.S. manufacturing ecosystem.

Transforming Central Texas

The expansion solidifies Bastrop’s role within a growing Central Texas manufacturing and technology corridor extending from Austin to surrounding communities.

SpaceX joins a growing roster of high-tech employers attracted to Texas’ pro-business climate, workforce availability, and strategic proximity to national markets.

Sources:

“SpaceX plans massive $280M expansion in Bastrop,” San Antonio Express-News, December 2025.

“Governor Abbott Announces Texas Semiconductor Innovation Fund Grant to SpaceX,” Governor Greg Abbott Office of Communications, March 2025.

“SpaceX to make $280M investment in Bastrop facility, awarded Texas grant,” Austin Business Journal, March 2025.

“SpaceX Starlink expansion in Central Texas could speed hardware to East Texas homes,” East Texas Banner, September 2025.

“Elon Musk is shaping another Texas company town,” Houston Chronicle, December 2025.