In September 2025, Panasonic Energy made a significant announcement that jolted the electric vehicle industry.

The Japanese tech titan unveiled a bold new battery design that eliminates one of the most crucial components of modern lithium-ion cells—the anode.

Panasonic, whose technology powers millions of Teslas, claims the breakthrough could transform the range of EVs on a single charge. The announcement sent manufacturers racing to evaluate what this could mean for the future of clean transportation.

For Tesla owners, the impact could be significant: more extended range, lighter batteries, and reduced charging stress.

The Partnership Pedigree

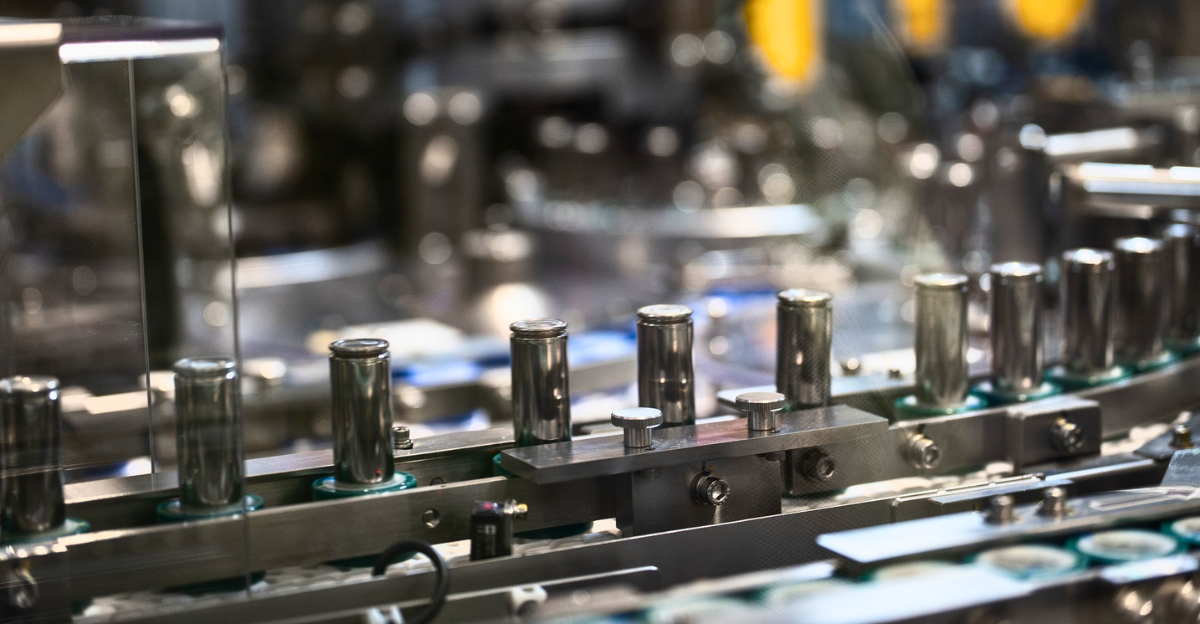

Panasonic has been Tesla’s closest battery ally since 2009, when it first began producing lithium-ion cells for the Model S.

The relationship deepened over the years, with $30 million invested in 2010 and an enormous $1.6 billion poured into Nevada’s Gigafactory in 2014—a facility that revolutionized high-volume EV battery production.

Since then, Panasonic has expanded to the 4.7-million-square-foot Kansas factory, which began mass production in mid-2025 with a yearly output target of 32 gigawatt-hours. Few companies can claim such a deep history in scaling advanced battery systems.

The Traditional Formula

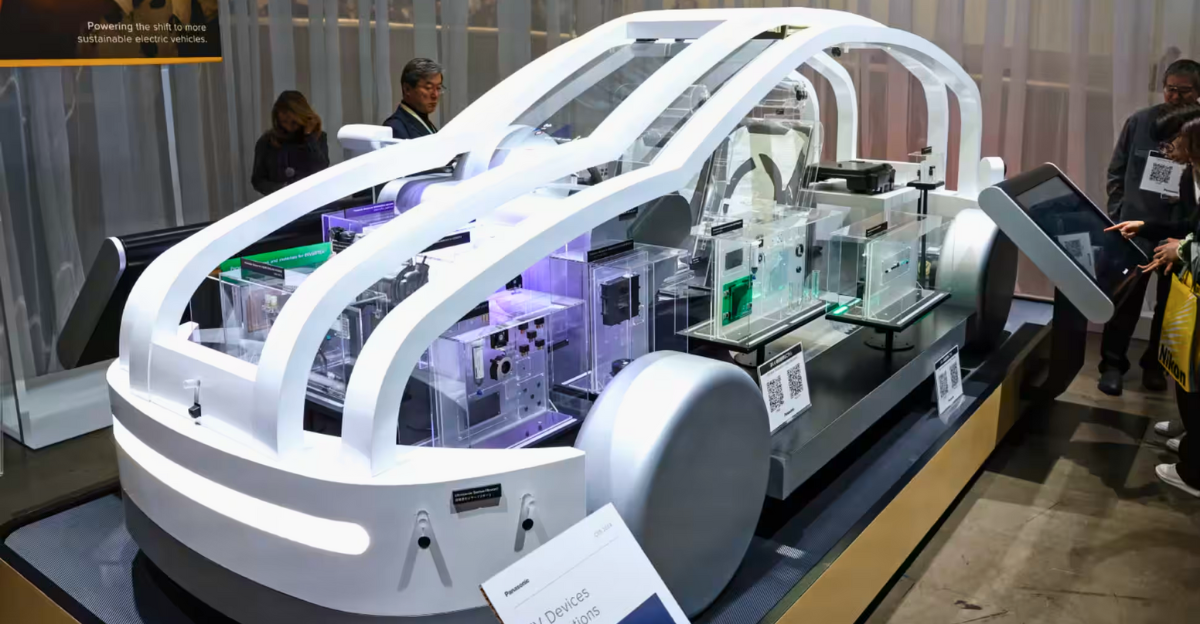

To appreciate the breakthrough, it is helpful to recall how standard batteries function. Conventional lithium-ion cells have three main layers: the cathode (positive side), the anode (negative side), and the separator that keeps them apart.

Manufacturers make nearly all anodes from graphite, a stable carbon material that hosts lithium ions during charging. Graphite is inexpensive, safe, and proven, which is why battery factories from Nevada to Shenzhen continue to rely on it.

However, graphite occupies valuable space inside the cell that engineers could otherwise use to hold capacity-rich cathode materials, such as nickel, cobalt, or aluminum.

Range Anxiety’s Grip

One big reason EVs haven’t completely replaced gasoline vehicles is psychological: range anxiety.

Surveys show most Americans want more than 300 miles of range; 400 miles is the number that finally makes them comfortable taking road trips.

Tesla’s popular Model Y Long Range offers around 350 miles today—impressive, yet not enough to completely alleviate anxiety.

Drivers still worry about finding chargers on long routes, especially in rural areas or during cold weather when efficiency drops. Extending range even modestly can make EV ownership feel just as practical and worry-free as owning a gas car.

The Anode Vanishes

Panasonic’s new design aims to achieve that goal by breaking away from the traditional template. Instead of installing an anode layer during manufacturing, Panasonic leaves that space empty.

When operators charge the battery for the first time, lithium metal naturally forms on the current collector, creating a “self-built” anode inside the cell.

It’s counterintuitive but incredibly effective: by removing the preassembled graphite structure, Panasonic frees up valuable space to include up to 25% more active cathode material.

More cathode means more energy storage, without increasing battery size.

The 90-Mile Promise

For the Tesla Model Y, this could translate to roughly 90 additional miles of range, jumping from approximately 350 miles to around 440.

That closes the psychological gap between EVs and gasoline vehicles. Alternatively, Panasonic could utilize the space savings to design more compact, lightweight battery packs that are less expensive to produce, thereby making EVs more affordable without compromising driving range.

This would give Tesla the flexibility to either pursue long-range vehicles or deliver more affordable cars—the two primary goals among consumers deciding whether to go electric.

Real-World Impact

What would 90 extra miles really mean? For most commuters driving about 50 miles daily, it’s nearly two more workweeks between plug-ins.

For families on road trips, it may mean one less charging stop on a 500-mile journey. Tesla drivers regularly share stories of “range anxiety” moments—rolling into Supercharger stations with nearly empty batteries or waiting in line for a free stall.

The added range won’t just be convenient; it will make EV driving less stressful, providing crucial flexibility in various weather conditions, traffic, and remote areas.

The Cost Equation

Beyond performance, Panasonic’s design could simplify the manufacturing process. Traditional anodes require layering, coating copper foils in a graphite slurry, compressing, and drying—all of which are costly and energy-intensive steps.

Eliminating that process streamlines production and reduces material usage. Additionally, the company plans to reduce its reliance on cobalt by utilizing less expensive metals, such as nickel and aluminum.

With this dual assault on cost and capacity, Panasonic hopes to lower dollars per kilowatt-hour, potentially reshaping EV affordability. However, executives declined to say whether consumers would see cheaper Teslas in showrooms anytime soon.

The Chinese Shadow

This innovation comes as Chinese battery makers dominate the global market, with CATL commanding nearly 38% of the market share and BYD over 17%. Together, they control the flow of raw materials and supply more than half the world’s EV batteries.

Both are racing toward all-solid-state technologies that could achieve astonishing energy densities by 2027. Panasonic’s anode-free model is Japan’s counterattack—a move to reassert leadership in next-generation cells and challenge China’s dominance in this field.

Experts estimate that China will produce about 70% of the world’s lithium-ion batteries by 2027, meaning Japan and its U.S. partners have a shrinking window to compete effectively.

The Hidden Engineering Challenge

Of course, there’s a catch: dendrites. These are tiny, needle-like lithium structures that can form during charging if ions deposit unevenly. Left unchecked, dendrites can pierce the battery’s separator and cause short circuits—sometimes leading to dangerous fires.

Conventional graphite anodes prevent this by neatly absorbing lithium ions between their carbon layers. In contrast, lithium metal has no structured “home” inside the cell; it must form evenly on a flat copper surface.

Panasonic must develop new electrolytes and surface treatments to ensure uniform growth and long-term stability. The entire project hinges on solving this single issue safely at scale.

Tesla’s Market Pressures

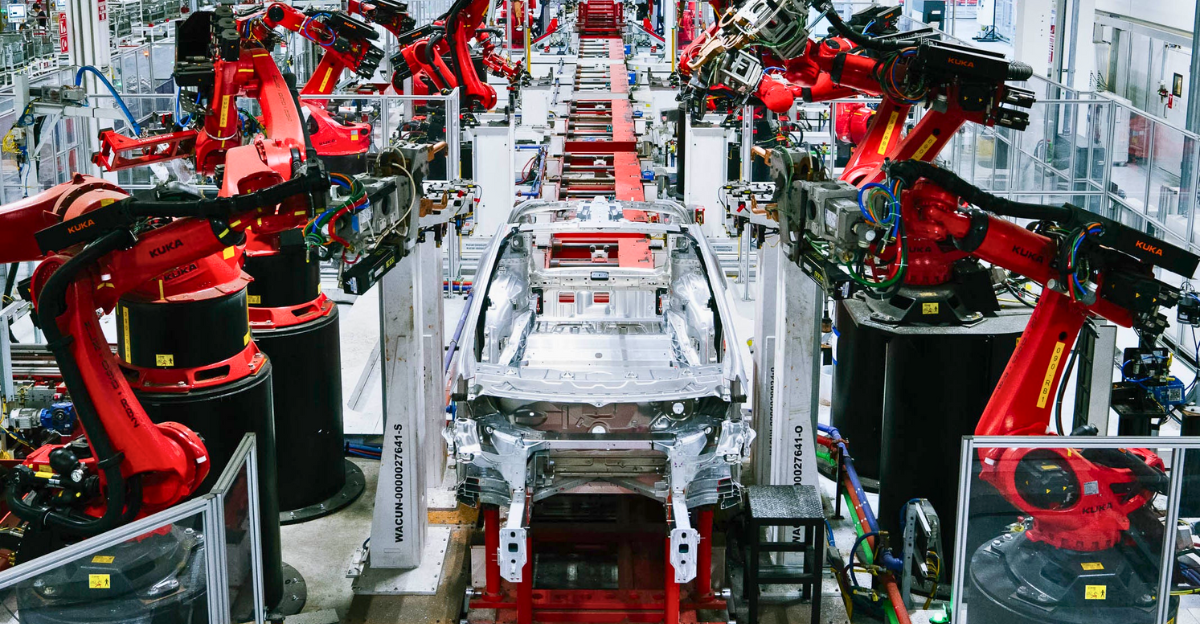

Tesla needs this breakthrough more than ever. Its U.S. market share dropped below 40% in 2025 as competition surged. In China and Europe, BYD, Volkswagen, and Hyundai have eaten into market share, with Tesla’s deliveries falling 13% in the first half of the year.

Critics accuse the company of letting its lineup stagnate while rivals release fresh, more affordable models.

A battery that leapfrogs competitors on range could restore Tesla’s technical edge and reinvigorate demand—particularly if it arrives before CATL and BYD’s rival solid-state batteries hit the market.

The Timeline Reality Check

Panasonic’s target of late 2027 for “world-leading capacity” fits real-world industrial timelines. Battery development isn’t fast: companies spend about two years building the factory, another year installing equipment, and one year fine-tuning operations before commercial production begins.

Panasonic already has infrastructure running in Nevada and Kansas, so experts believe the anode-free design could reach pilot-scale testing by late 2026.

If all goes well, we could see the first mass-market Tesla vehicles utilizing these advanced cells around 2028 or 2029—just in time to challenge new models from Chinese and Korean automakers.

Solid-State Convergence

Parallel to this, Panasonic is also developing solid-state batteries, with prototype samples due by 2027. Unlike current lithium-ion designs, solid-state batteries replace liquid electrolytes with solid materials, offering higher energy density and superior thermal safety.

For now, Panasonic plans to utilize them first for humanoid robots and industrial machinery, where small size and high durability are most important.

However, rivals like Toyota and Sumitomo are racing to integrate solid-state systems directly into electric cars by the late 2020s.

By converging both approaches, Panasonic hopes to cover multiple market segments across robotics, consumer electronics, and vehicles.

The Nickel Balancing Act

High-nickel cathodes remain central to maximizing battery capacity, but they bring trade-offs. Nickel increases output but also raises thermal instability and moisture sensitivity.

Traditionally, cobalt has stabilized these reactions, but cobalt is costly and controversial due to concerns about mining ethics. Panasonic aims to use advanced coatings and dopants to stabilize higher-nickel chemistry while cutting cobalt content.

So rather than pursuing risky 90% nickel levels, the anode-free approach increases overall energy storage volume inside the cell—a safer, smarter route toward high density.

The Regulatory Wildcard

New battery technology doesn’t develop in a policy vacuum. U.S. electric vehicle tax credits tied to domestic content are critical to competitiveness.

Panasonic’s massive Kansas plant benefits from these incentives, producing locally to qualify under the Inflation Reduction Act. However, political changes after 2026 could revisit tariff policies or modify content requirements.

Japan’s 2023 bilateral agreement with the U.S. allows Panasonic to enjoy domestic-equivalent treatment for credits; however, the long-term stability of these rules remains uncertain.

Market rollout by 2027 will depend on maintaining favorable policy environments for EV manufacturing collaboration between the U.S. and Japan.

The Patent Race

The race for dominance is also intellectual in nature. Dozens of academic and corporate labs are filing patents covering anode-free lithium innovations—primarily in controlling dendrites and managing solid-electrolyte interfaces.

Japanese, Chinese, and Korean firms are all pursuing proprietary electrolyte blends and surface treatments that could make or break the commercialization of their products.

Panasonic will likely keep its unique manufacturing process secret until it finalizes the patents, including how it triggers the safe formation of lithium metal during the first charge.

The Recycling Question

Every major shift in chemistry reshapes recycling. Current recycling plants optimize their processes for graphite anodes and conventional cathode ratios.

Removing the graphite layer changes both material flow and recovery economics. The new design increases the valuable nickel and cobalt content, raising potential recyclability profits—but the formation of lithium metal inside the cell complicates the reclaiming of raw lithium.

Panasonic and Tesla already operate recycling programs for traditional packs, but updated systems will be needed to manage future waste responsibly and economically as these technologies mature.

Social Media Speculation

As soon as Panasonic’s announcement dropped, Tesla fan communities exploded with excitement. Enthusiasts on X (formerly Twitter) and Reddit celebrated the news, predicting “500-mile Teslas” within three years.

Others were more cautious, noting 2027 would only mark the start of production, not widespread rollout. Some online rumors even claimed Tesla could retrofit existing vehicles with the new cells—a technical and economic impossibility given completely different pack geometries.

Still, the internet energy reflects how deeply consumers link battery progress with confidence in EV adoption. More extended range equals more buyers—that much is clear.

Echoes Repeating

Panasonic’s breakthrough isn’t the first time EV batteries have upended expectations. In the 1990s, Sony’s lithium-ion batteries replaced nickel-cadmium batteries, revolutionizing the electronics industry.

Tesla’s 2012 Model S proved long-range EVs could go mainstream. And Toyota’s hybrid systems set efficiency benchmarks two decades ago. Each time, skeptics doubted the feasibility, and each time, engineering breakthroughs reshaped industries.

Now the cycle repeats. Anode-free batteries promise both efficiency and simplicity—if Panasonic can solve the issue of dendrite stability. History suggests technological leaps always carry risk but reshape markets when successful.

The Verdict

Panasonic’s anode-free battery could be the most consequential EV innovation since lithium-ion went commercial three decades ago.

The benefits are tangible—25% higher capacity, up to 90 extra miles of range, or smaller, lighter, cheaper battery packs. But the hurdles are serious: dendrite suppression, mass production stability, and cost scaling.

If Panasonic succeeds, Tesla could reclaim leadership in range and efficiency by 2028–2029, just as global EV competition peaks.

The following 24 months will determine whether Japan’s iconic technology brand can reinvent lithium-ion once again—or whether Chinese solid-state rivals will seize the crown first.