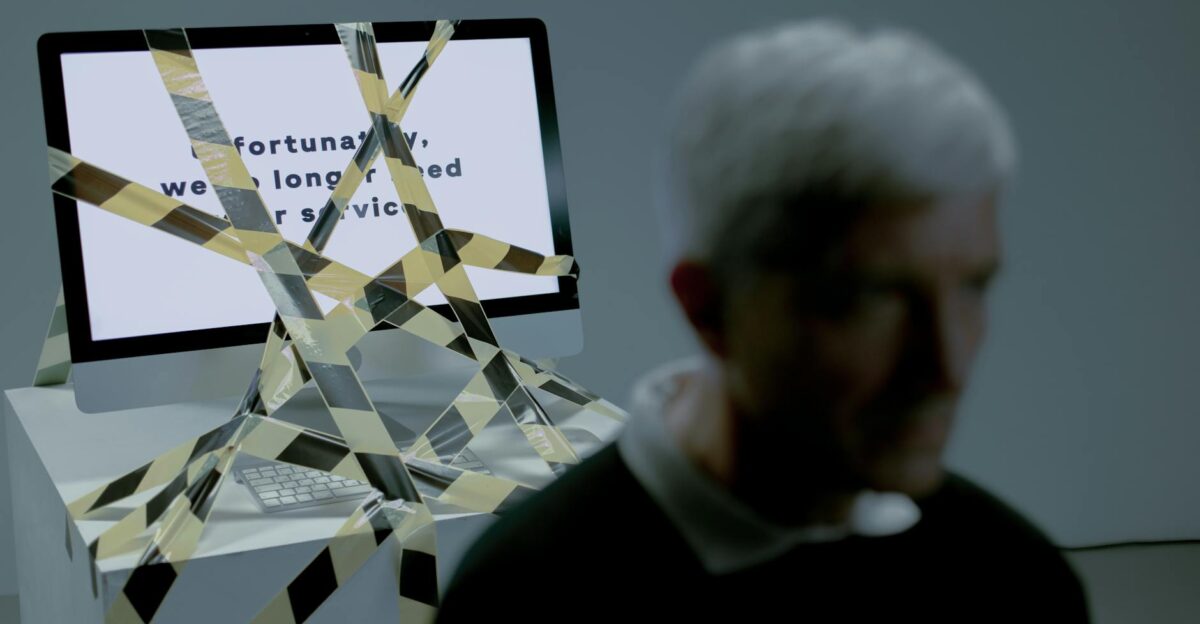

The WARN notice is already filed. A permanent closure is stamped into the record. Inside Washington County Industrial Park in Telford, Tennessee, a manufacturing plant is now on a countdown to silence—one that will erase 136 jobs and pull millions in annual wages out of the town.

The layoffs won’t happen all at once, but the outcome is locked in, and the clock is already running. But this shutdown is only the visible edge of a much larger pressure bearing down on East Tennessee’s manufacturing base…

Plant Shutdown Looms

East Tennessee’s manufacturing base is bracing for impact. A WARN notice filed in early December confirms that a major automotive supplier will permanently close its Telford facility. Layoffs are scheduled to roll out in phases, beginning April 30 and concluding by August 31, 2026.

For workers, the timeline stretches uncertainty across the summer months, turning what once felt like steady industrial employment into a countdown toward unemployment.

Automotive Roots Run Deep

The Telford plant has long been part of the region’s industrial backbone. Operated by JTEKT North America, the facility produced automotive bearings and steering components for North American markets.

Located inside Washington County Industrial Park, it sustained generations of families. But as the automotive sector recalibrates around cost pressures and consolidation, even long-standing sites like this one are no longer immune.

Supply Chain Pressures Mount

Across the U.S., automotive suppliers are under strain. Weak freight demand, electric-vehicle transitions, and corporate consolidation have triggered a wave of factory closures. Recent examples include Ford’s battery plant pivot in Kentucky and trailer manufacturer layoffs in Pennsylvania.

Tennessee has not been spared, with logistics and industrial job cuts piling up. The pressure has tightened steadily, pushing facilities like Telford closer to the edge.

Closure Officially Confirmed

The decision is final. JTEKT North America filed a WARN notice on December 4 confirming the permanent shutdown of its Telford manufacturing operation. Layoffs will begin in late April 2026, with all 136 employees expected to be affected by the end of August.

Once operations cease, the Washington County Industrial Park facility will go quiet—ending an era of production that once anchored the local workforce.

A Local Economy Hollowed Out

For Telford, the closure means far more than lost jobs. The 136 manufacturing positions represent approximately $10-11 million in direct annual wages based on automotive parts manufacturing compensation data from the Motor Equipment Manufacturers Association.

Using industry multiplier analysis from the MEMA Economic Impact Study—a comprehensive national assessment of motor vehicle parts manufacturing—each direct job in this sector generates 4.5 additional positions throughout the region through supply-chain purchases and worker household spending.

Workers Face Harsh Choices

As a result, the 136 direct job losses will eliminate approximately 612 total positions in the regional economy, representing an estimated $15-18 million in total annual wage impact across all local sectors. That income once supported housing, schools, restaurants, and small businesses.

In rural economies, where one employer often drives local spending patterns, the shock reverberates quickly and deeply. Employees who remain through the closure date will receive severance, and some workers may apply for transfers to other JTEKT facilities in Morristown, Vonore, or South Carolina.

But relocation is not a simple option for many. Family ties, housing costs, and commuting distances limit mobility. For long-tenured workers, loyalty to the plant now ends in forced transition rather than retirement.

Rapid Response Steps In

State agencies have moved quickly. The Tennessee Department of Labor and Workforce Development received the WARN notice and activated a rapid response team through the Northeast Workforce Development Board and First Tennessee Development District.

The effort includes reemployment services, training programs, and job placement assistance. Officials hope early intervention can soften the blow—but replacing specialized manufacturing work in a rural market remains a tall challenge.

Supply Chain Ripples Spread

The shutdown reflects broader shifts in automotive manufacturing. JTEKT continues operating other facilities in Tennessee, but the loss of the Telford plant signals ongoing consolidation. Nationally, similar restructuring has followed EV investment realignments and prolonged demand softness.

While regulators track WARN compliance, the downstream effects—supplier gaps, workforce displacement, and local economic stress—continue to accumulate.

Manufacturing Layoffs Accelerate

Recent weeks have seen significant manufacturing and logistics job reductions nationwide, with manufacturers cutting positions in response to electric-vehicle transitions and demand weakness. Food processing, EV battery production, and trailer manufacturing have all taken hits.

Southern states, including Tennessee, have experienced a growing share of these losses. Even as some freight indicators stabilize, factory closures continue, reinforcing concerns that the industrial slowdown is structural rather than temporary.

The Transfer Reality

On paper, transfer opportunities soften the announcement. In practice, relocation remains a steep challenge for many Telford workers. Long commutes, childcare obligations, and housing constraints limit feasibility.

The result is a stark reality: most of the 136 jobs vanish locally. That gap amplifies the estimated wage loss and deepens frustration among families who feel left behind by corporate consolidation.

Community Voices Grow Louder

Residents and workers describe the closure as a devastating blow to rural East Tennessee. Many employees spent decades at the plant, expecting stability that never returned.

With limited relocation options, anger and anxiety have surfaced at community meetings. Local leaders are urging state support and redevelopment efforts, while workers demand acknowledgment of the human cost behind efficiency-driven decisions.

JTEKT’s U.S. Footprint Shifts

JTEKT North America employs roughly 5,000 workers across 23 facilities in the United States. The closure of the Telford site marks a strategic pullback rather than a full retreat from Tennessee, with other plants remaining active.

While the company has not publicly detailed the exact reasons for selecting Telford, the move aligns with broader efforts to streamline operations amid industry transformation.

Can Aid Replace Industry?

Workforce agencies are organizing job fairs, resume workshops, and retraining programs aimed at displaced manufacturing workers. Partnerships with logistics and regional employers offer some pathways forward.

Still, replacing 136 specialized industrial jobs in a rural area is difficult. Even successful retraining may mean lower wages, longer commutes, or entirely new careers—none of which fully restore what was lost.

An Uncertain Road Ahead

As the plant’s final months tick down, Telford faces an uncertain future. The loss of a major employer removes both income and identity from the community.

State assistance offers hope, but the elimination of $10-11 million in annual direct wages—and $15-18 million in total economic impact—leaves a lasting mark.

With automotive consolidation continuing into 2026, residents are left asking whether new industries can arrive before the economic vacuum deepens further.

Sources:

“JTEKT North America Corporation LLC TDLWD WARN Letter.” Tennessee Department of Labor and Workforce Development, Dec 4, 2025.

“JTEKT closure to affect 136 employees in Telford.” Times News, Dec 7, 2025.

“The Economic Impact of the Motor Vehicle Parts Manufacturing Industry on the United States.” Motor & Equipment Manufacturers Association, Aug 2016.

“JTEKT North America in Telford to close facility, more than 100 employees affected.” WCYB, Dec 4, 2025.