A laboratory breakthrough in Japan could reshape how cars and aircraft are engineered. Researchers at Nagoya University have developed a 3D‑printable aluminum alloy that stays strong and flexible at temperatures up to 300°C (572°F), a range that normally forces designers to rely on much heavier and more expensive metals. The work, published in the Nature‑portfolio journal Nature Communications in December, points to lighter engines, more efficient vehicles, and a new way of thinking about how metals are made for high‑temperature use.

Breaking a Century of Metallurgical Assumptions

For decades, iron has been treated as an unwanted impurity in aluminum. Even small amounts tend to make conventional aluminum alloys brittle and more vulnerable to corrosion, so manufacturers have avoided adding it on purpose. The Nagoya team has effectively broken that “rule” by exploiting the extreme conditions inside modern metal 3D printers.

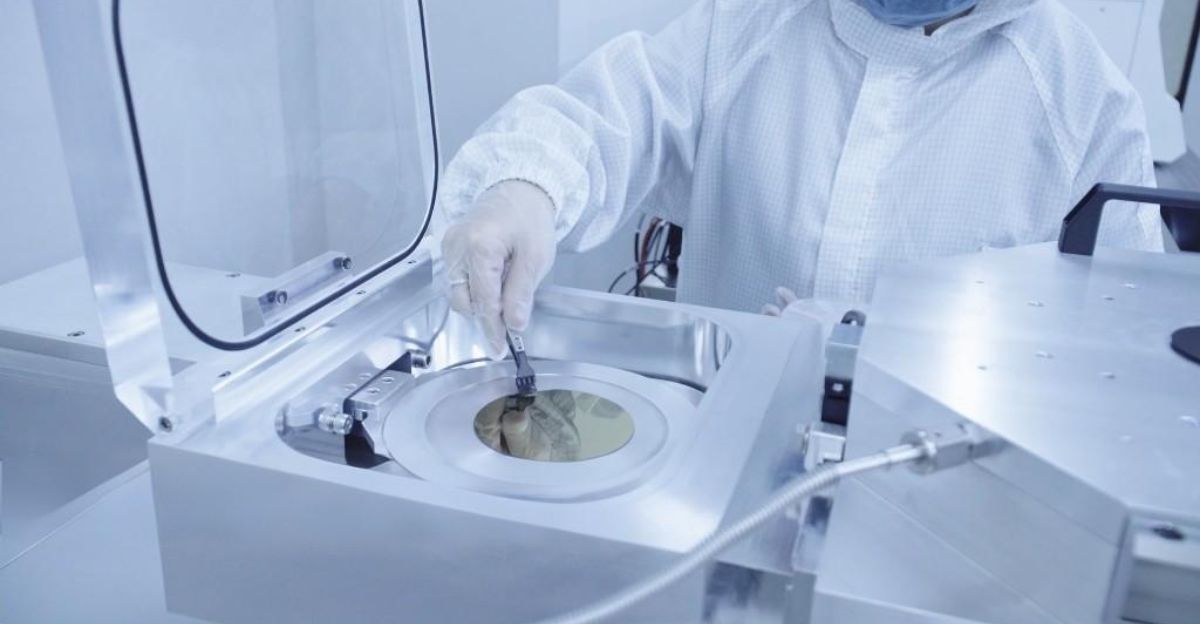

Using laser powder bed fusion, a process in which a laser melts metal powder layer by layer, the alloy solidifies at cooling rates estimated between roughly 103 and 108 kelvin per second—orders of magnitude faster than in traditional casting. According to project leader Professor Naoki Takata, these ultra‑fast cooling rates trap iron atoms in microstructures that cannot form under equilibrium conditions. Instead of creating weak, brittle phases, the iron becomes a key contributor to strength when combined with other carefully chosen elements.

By rethinking iron’s role under these non‑equilibrium conditions, the researchers show that a long‑avoided element can become an asset when paired with the right manufacturing method and microstructural design.

Engineering a New Aluminum Formula

After testing multiple combinations, the team settled on an aluminum‑iron‑manganese‑titanium system, often referred to as Al‑Fe‑Mn‑Ti. At room temperature, test samples reached tensile strengths of about 390 megapascals while still stretching 14–17 percent before breaking, a balance of strength and ductility unusual for aluminum designed specifically for 3D printing.

Each element serves a distinct function. Manganese helps stabilize critical microstructural phases at elevated temperatures, ensuring the alloy does not soften dramatically under heat. Titanium forms fine particles that refine the grain size of the metal to roughly 2.3 micrometers, improving both strength and toughness. Iron, once the “contaminant,” is locked into beneficial configurations by the rapid solidification of laser processing.

The result is an alloy tailored from the atomic scale upward specifically for additive manufacturing, rather than adapted from recipes developed decades ago for casting or forging.

Holding Strength at 300°C and Improving Printability

Conventional aluminum alloys typically lose much of their load‑bearing capacity above about 200°C, which is why critical engine and exhaust components are usually made from steels, titanium, or nickel‑based superalloys. In tests, the new Al‑Fe‑Mn‑Ti material maintained both high strength and useful ductility at 300°C, with performance remaining almost unchanged even after 100 hours at that temperature.

This level of thermal stability addresses one of aluminum’s core weaknesses and opens the door to using it in areas of vehicles and aircraft that have long been off‑limits. Just as important for manufacturers, the alloy also behaves better inside the printer. Many high‑strength aluminum grades are prone to cracking or warping during 3D printing, a problem that has limited industrial adoption. The Nagoya group reports that its new compositions show markedly improved printability, making them easier to process reliably at scale.

Because laser powder bed fusion allows intricate shapes and internal channels, engineers can pair the alloy’s properties with complex geometries for further weight and performance gains—especially in components exposed to high temperatures.

Weight, Fuel Use, and Environmental Stakes

The potential impact on vehicle weight is substantial. Industry and government research show that cutting a vehicle’s mass by about 10 percent can improve fuel economy by roughly 6–8 percent, depending on the powertrain and drive cycle. Aluminum components can weigh 40–65 percent less than comparable steel parts, and some all‑aluminum designs have achieved overall vehicle weight reductions on the order of 20–30 percent or more. The new high‑temperature aluminum alloy makes it more feasible to extend such savings into engine bays and other hot zones that previously demanded heavier metals.

Real‑world projects hint at what might be possible. Renault Trucks, for example, used metal 3D printing to redesign a four‑cylinder diesel engine, trimming around 120 kilograms—about 25 percent of its weight—while also cutting the number of parts by roughly a quarter. Similar strategies, combined with heat‑resistant aluminum, could further reduce engine masses and simplify assemblies by integrating multiple functions into single, printable components.

Every kilogram matters for emissions. Studies indicate that removing 100 kilograms from a vehicle can lower carbon dioxide emissions by around 9 grams per kilometer. A 10 percent reduction in weight typically yields a 6–8 percent decrease in fuel consumption, along with corresponding drops in greenhouse gas output. Lighter vehicles can also use smaller engines, transmissions, and differentials, amplifying the benefits through secondary weight reductions across the drivetrain.

Against that backdrop, a realistic target of around 20 percent weight reduction in certain vehicle platforms—by combining advanced alloys with optimized designs—has become a key focus for automakers pursuing stricter efficiency and emissions goals.

Cost, Recyclability, and Aerospace Potential

Cost and sustainability are central to the Nagoya approach. The new alloys rely on abundant, relatively inexpensive elements: iron, manganese, and titanium. That contrasts sharply with titanium‑rich superalloys and nickel‑based systems, which are typically far more expensive and heavier. Titanium itself, a staple for high‑temperature aerospace parts, can cost roughly an order of magnitude more per kilogram than aluminum and is about two‑thirds heavier by volume. If heat‑resistant aluminum can take over selected titanium roles, material costs could fall by as much as 80–90 percent in those components while also reducing mass.

The researchers also designed the composition with recycling in mind, an important factor as regulators and manufacturers push to lower the environmental footprint of metal production and end‑of‑life disposal. Better control of alloying elements improves scrap handling and supports a more circular materials flow, particularly in sectors such as automotive where large volumes of metal circulate through the system.

Aerospace manufacturers stand to gain from a material that bridges the gap between low‑density aluminum and high‑temperature superalloys. Turbine components, compressor structures, housings, and hot structural elements demand both heat resistance and low weight. A 300°C‑capable aluminum alloy, printable into complex shapes with internal cooling channels, offers a new option between conventional aluminum and much heavier nickel‑based systems for moderately hot sections.

Beyond Aluminum: A New Path for Alloy Design

The Nagoya alloy emerges against a backdrop of rapid progress in metals tailored for additive manufacturing. Researchers at MIT have used machine‑learning tools to design aluminum alloys reported to be several times stronger than conventional versions and stable up to about 400°C. Oak Ridge National Laboratory has introduced DuAlumin‑3D, optimized for creep resistance at 300–400°C, while teams at Tianjin University and elsewhere have pushed aluminum‑based systems toward service temperatures near 500°C using finely dispersed oxide nanoparticles.

Meanwhile, the industrial base for metal 3D printing is expanding quickly. Forecasts suggest the automotive segment of the broader 3D‑printing market could grow from around USD 4–5 billion in the mid‑2020s to more than USD 25 billion by the early 2030s. Carmakers such as Porsche, Ferrari, and BMW are already deploying additively manufactured parts—from lightweight pistons with integrated cooling channels to suspension, structural, and cylinder‑head components—seeking better performance, reduced part counts, and more efficient cooling.

Technical hurdles remain. Current laser powder bed fusion systems still face limits in build volume, throughput, and consistency when scaled to mass production. Next‑generation machines with larger chambers in the 600–1000 millimeter range are being developed to handle medium and small parts in higher volumes, while researchers refine process control and in‑situ monitoring to ensure uniform properties across large batches.

Professor Takata has emphasized that the underlying approach is broadly applicable. By understanding how alloying elements behave under the extreme thermal cycles of 3D printing, scientists can design entirely new classes of metals—not only aluminum—that are optimized from the outset for additive manufacturing. With automotive and aerospace companies already partnering with universities and laboratories around the world, many analysts expect rapid commercialization of such alloys within the next three to five years.

If those projections hold, the Nagoya alloy may mark more than a single materials advance. It could signal a wider shift in metallurgy, where elements once dismissed as contaminants become central tools in designing lighter, more efficient machines—and help the auto industry move closer to the 20 percent weight‑cut targets needed for a lower‑carbon future.

Sources:

“Design of high-performance sustainable aluminum alloy for additive manufacturing.” Nature Communications, December 2025.

“How 3D printing creates stronger vehicle parts by solving aluminum’s high-temperature weakness.” Nagoya University Graduate School of Engineering News Release, December 2025.

“Printable aluminum alloy sets strength records, may enable lighter aircraft parts.” MIT News, October 2025.

“Advancing Metal 3D Printing Through Real-Time Process Control.” Highways Today, November 2025.

“Metal 3D printing enables lighter Renault engines.” Electronic Specifier, July 2025.

“Exploring Metal 3D Printing Applications in Automotive.” Zone 3D Plus, May 2025.

“Lightweighting cost impacts on market adoption and greenhouse gas emissions reduction.” National Renewable Energy Laboratory (NREL), 2025.

“Lightweight Materials for Cars and Trucks.” U.S. Department of Energy Vehicle Technologies Office, 2025.