General Motors has delivered a significant blow to its manufacturing workforce just before the holidays, announcing extended shutdowns at two major American facilities. The decision impacts approximately 6,000 workers across Michigan and Kentucky, who find themselves facing temporary layoffs during the festive season.

The move centers on the company’s oldest continuously operating factory, signaling a major pause in production for some of the automaker’s most profitable vehicles.

Historic Flint Assembly Goes Dark

The most substantial closure affects the historic Flint Assembly plant in Michigan, a cornerstone of GM’s manufacturing footprint since 1947. Roughly 5,000 hourly workers at this facility will stop production on Christmas Eve, with assembly lines remaining silent for more than a month.

The plant is not scheduled to resume operations until January 26, 2026, marking an exceptionally long break compared to traditional holiday downtime.

Profitable Trucks on Hold

Flint Assembly is critical to GM’s bottom line, serving as the heavy-duty hub for the Chevrolet Silverado and GMC Sierra pickup trucks. These heavy-duty models are among the highest-margin vehicles in the company’s portfolio, making a five-week production halt largely unprecedented.

The extended downtime suggests that GM is prioritizing significant internal changes over immediate output, despite the sustained market demand for these rugged trucks.

The Official Explanation

In an official statement, General Motors described the extended pause at Flint as necessary for “planned maintenance and project work.” A company spokesperson emphasized that the downtime would be utilized to complete essential updates within the facility.

While large-scale maintenance is common during the holidays, a shutdown extending well into late January points to infrastructure projects far more complex than routine equipment servicing or cleaning.

Secret Retooling Projects?

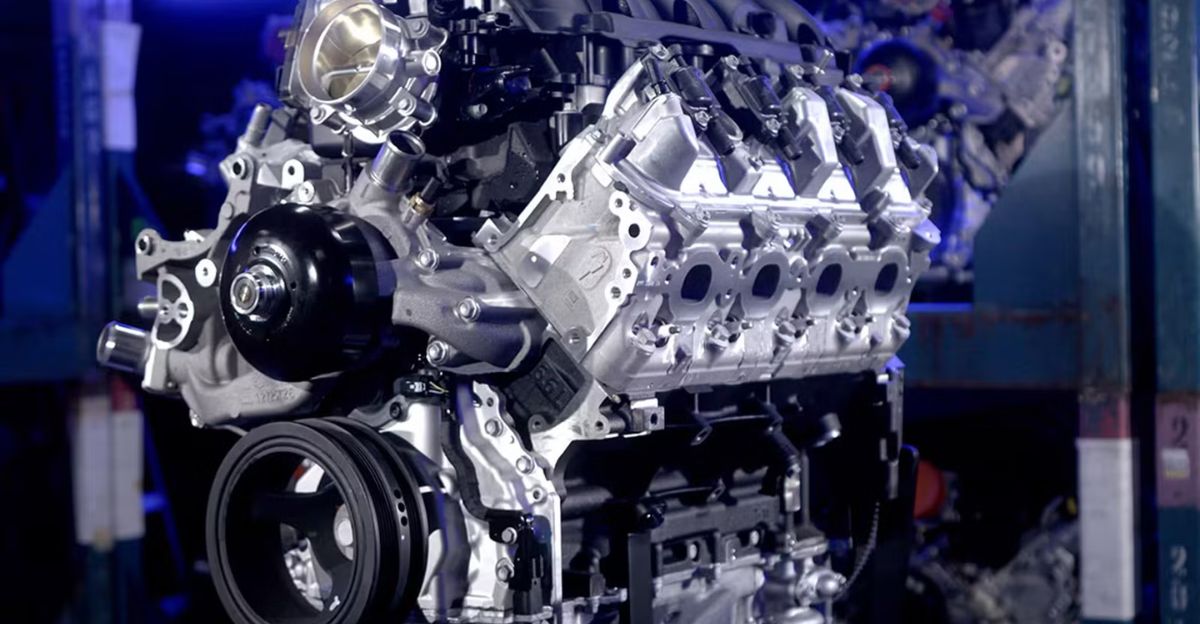

Industry analysts speculate that “project work” is a euphemism for retooling assembly lines for future products. Experts believe the plant is being prepared for the next generation of heavy-duty trucks, potentially including updates for the rumored sixth-generation small-block V8 engine.

If accurate, this shutdown represents a critical investment in the facility’s longevity, ensuring Flint remains capable of building modern combustion-engine trucks for years to come.

Corvette Plant Joins the Shutdown

The shutdown wave also crashed onto the shores of Bowling Green, Kentucky, the exclusive home of the Chevrolet Corvette. Production at this iconic facility halted even earlier, with lines stopping on December 15.

Approximately 1,100 workers at the plant have been sent home and are not expected to return until January 12, 2026. This nearly month-long hiatus leaves the sports car factory quiet through the New Year.

Managing Inventory Buildup

Unlike the truck plant, the pause at Bowling Green appears driven by simple supply and demand economics. Dealership inventories of the Corvette have swelled recently, with thousands of 2025 and 2026 models currently sitting on lots.

Winter is traditionally a slow sales season for high-performance sports cars, prompting GM to throttle back production to prevent an oversupply of inventory that could degrade the vehicle’s premium value.

Union Leaders Urge Calm

Local union leaders have moved quickly to reassure their members that these layoffs are strictly temporary.

Charles Laster, president of UAW Local 2164 in Bowling Green, publicly confirmed the situation, stating that while the majority of the workforce is being laid off, everyone is expected to return. His comments aimed to quell fears that these temporary measures could morph into the permanent job losses seen elsewhere in the industry.

Financial Strain on Families

Despite assurances of a return, the timing of the layoffs strikes a harsh chord for employees. Being sent home right before Christmas creates financial anxiety and disrupts holiday planning for thousands of families.

While eligible UAW members typically receive supplemental pay during temporary shutdowns to bridge the gap between state unemployment benefits and their regular wages, the psychological toll of an empty factory during the holidays remains significant.

Contrast with EV Cuts

These temporary halts stand in stark contrast to recent permanent cuts in GM’s electric vehicle division. Just months ago, the automaker slashed roughly 1,000 jobs at its Factory Zero EV plant in Detroit and other electric-focused sites.

Those reductions were driven by softer-than-expected adoption of electric vehicles, forcing GM to recalibrate its workforce. The current shutdowns, conversely, affect healthy internal combustion product lines.

A Symbol of Resilience

The historical weight of the Flint Assembly plant adds gravity to its silence. Opening just after World War II, the factory has survived decades of industry upheaval to become the longest-running plant in GM’s network. It famously built the very first Corvette in 1953 before that line moved elsewhere.

Today, it remains a symbol of American industrial resilience, making a five-week closure a notable event in its storied timeline.

Strategic Balancing Act

This dual shutdown highlights the complex balancing act GM is performing between maintaining profitability and managing inventory.

By pausing both its highest-volume heavy-duty truck plant and its niche sports car facility, the company is fine-tuning its output to match market realities. It allows them to control costs at the end of the fiscal year while preparing their most critical assets for the 2026 production push.

Impact on High-Performance Engines

The ripple effects of the Bowling Green closure extend to the specialized Performance Build Center located within the plant. This facility is responsible for hand-assembling the high-performance engines used in top-tier Cadillac and Corvette models.

The pause means a temporary halt in the creation of the supercharged powerplants that define GM’s most exclusive vehicles, ensuring that the supply of these halo engines also tightens alongside the cars themselves.

Preparing for the Return

When operations resume in mid-to-late January, the pressure will be on to ramp production back up quickly. For Flint, the return will likely reveal whether the “project work” has indeed altered the production line for new models.

Workers will step back into a facility that may look different than the one they left, ready to churn out the profitable trucks that effectively subsidize the company’s electric transition.

Waiting Out the Winter

For now, the gates remain locked at two of America’s most famous automotive plants. Six thousand workers are waiting out the winter break, hopeful that the new year brings stability rather than further disruption.

As the auto industry continues to navigate a volatile economic landscape, these extended “holiday” shutdowns serve as a reminder of how quickly manufacturing priorities—and the lives of the workers who support them—can shift.

Sources

“GM Is Shutting Two Of Its Most Important Factories For Over A Month.” CarScoops, 15 Dec 2025.

“GM Halts 3/4-Ton and One-Ton Truck Assembly, Lays Off Workers.” MotorBiscuit, 13 Dec 2025.

“Corvette production pauses as Bowling Green plant plans extended holiday break.” The Auto Wire, 16 Dec 2025.

“Factory Shutdowns Raise Concerns Over GM’s Truck Production.” MI Tech News, 14 Dec 2025.